GrInHy

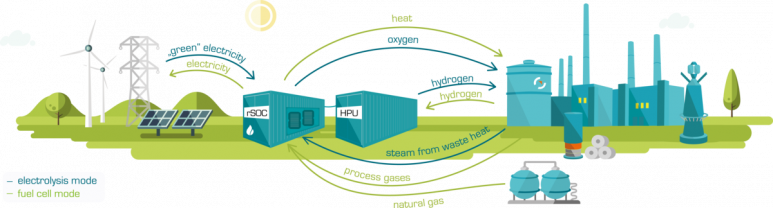

With its roadmap for moving to a competitive low-carbon economy in 2050, the European Commission sets greenhouse gas emissions targets for different economic sectors. A main challenge will be the integration of renewable energy sources into industrial processes to avoid carbon dioxide emissions.The vision of GrInHy is to provide green hydrogen via electrolysis and also to stabilize the grid at the same time as reversible generator. Because a significant share of the energy input is preferably provided in the form of waste heat, high-temperature electrolysis achieves higher electrical system efficiencies and, therefore, is one of the most promising technologies to fulfill this vision. Besides the steel industry, which is already addressed in the project, green industrial hydrogen can be used as a feed material for various industrial applications, e.g. in the chemical industry, food processing, metallurgy, glass production, electronics manufacturing and power plant generator cooling.

The GrInHy project targets the integration and validation of a High Temperature Electrolysis (HTE) at the industrial site of Salzgitter Flachstahl GmbH for hydrogen production. The developed electrolyser system shall be a scalable module capable of ranging from 150 kWAC to several megawatts. Based on available steam, the project aims at an overall electrical efficiency of more than 80 %LHV. Technology maturity will be proven through a total operation time of at least 7,000 h. In parallel, the quality of the stack module will be improved. The system is intended to operate as reversible generator. In the Solid Oxide Electrolyser Cell (SOEC) mode hydrogen will be produced, whereas the Solid Oxide Fuel Cell (SOFC) mode will generate electricity from gas to support the electrical grid during renewable energy shortages. The reversibility is a natural feature of the solid oxide cell technology developed by the partners in previous activities, and will result in a significant improvement of state of the art electrolysis economics.

Besides the demonstration of the technology under industrially viable conditions, a techno-economic analysis accompanies the development in order to evaluate potential additional business cases for the HTE technology in different markets beyond the iron and steel industry. The project aims at gathering practical data from an industrial sized system, to enable more precise predictions on future investment costs, efficiencies and durability.

GrInHy has 7 main objectives that can be divided into call-related objectives and additional objectives. Whereas the call-related objectives originate from the required scope and expected impact of the call, the additional objectives are related to their relevance for developing the technology towards a marketable product.

Call-related objectives:

- Proof of reaching an overall electrical efficiency of at least 80 %LHV (>95 %HHV);

- Scaling-up the SOEC unit to a AC power input of ca. 150 kWAC;

- Reaching a lifetime of greater 10,000 h with a degradation rate below 1 %/1,000 h;

- Integration and operation for at least 7,000 h meeting the hydrogen quality standards of the steel industry.

Additional objectives:

- Elaboration of an Exploitation Roadmap for cost reducing measures;

- Development of dependable system cost data;

- Integration of a reversible operation mode (fuel cell mode).

Web site

Web site