ICO2CHEM

ICO2CHEM is an EU Horizon 2020 project. It is funded through SPIRE, the European Public-Private Partnership dedicated to innovation in resource and energy efficiency enabled by the process industries. The project partners are VTT from Finland, INERATEC, Infraserv Höchst, ALTANA, and Provadis Hochschule from Germany, and Politecnico di Torino from Italy.

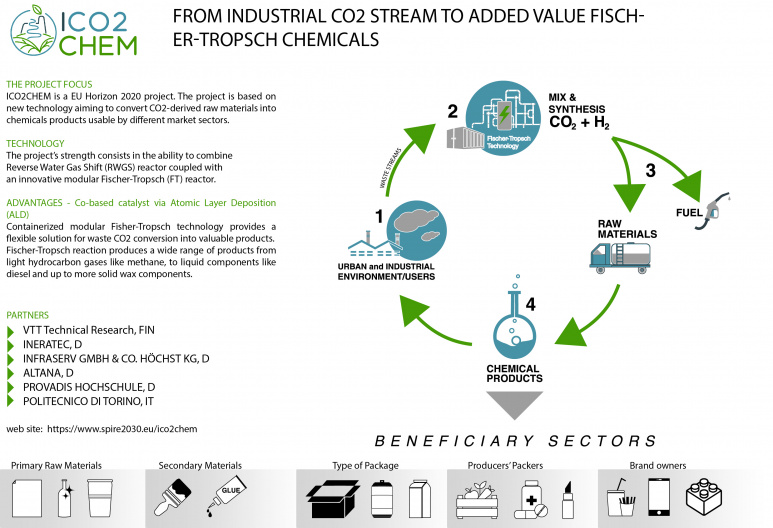

ICO2CHEM, being part of the call SPIRE08-2017 ‘Utilisation of CO2’, aims at developing a new production concept for converting waste CO2 to value-added chemicals. The focus is on the production of white oils and high molecular weight aliphatic waxes. The technological core of the project consists in the combination of a Reverse Water Gas Shift (RWGS) reactor coupled with an innovative modular Fischer-Tropsch (FT) reactor.

Within ICO2CHEM, a containerized chemical pilot plant will be installed and operated at the Industrial Park Höchst in Frankfurt, Germany. The pilot plant will convert CO2 from a biogas upgrading plant together with industrial H2, a by-product from a chlor-alkali electrolyzer plant, into highly valuable white oils and high molecular weight aliphatic waxes. The pilot plant consists of innovative RWGS and FT reactors, supplied by INERATEC. The RWGS step will convert CO2with H2 into a synthesis gas mixture. The following FT reaction step will convert the synthesis gas into the chemical products. The FT reactor will be equipped with a novel Co-based catalyst with enhanced selectivity and lifetime, supplied by VTT. The project partner Altana will utilize the white oils and wax emulsions as a raw material for chemical products, such as coatings and sealant materials, and benchmark the properties of the raw material against the fossil-based material.